Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

In the rapidly evolving landscape of polymer manufacturing, the selection of high-quality PVC granules has become fundamental for a broad array of industrial applications. According to the latest market analysis from the Plastic Industry Association, the global demand for PVC granules is projected to rise by approximately 4.5% annually through 2027, driven by their versatility and durability across sectors such as construction, automotive, and consumer products. Understanding the factors that influence the choice of PVC granules is crucial for engineers and manufacturers seeking to optimize performance and reduce costs in their projects.

Dr. Emily Chen, a noted expert in polymer science and a contributor to the Journal of Plastic Technology, emphasizes, “Selecting the right PVC granules for specific applications can significantly enhance product longevity and mechanical properties.” This insight underscores the importance of evaluating factors such as granule size, additives, and the intended use when making procurement decisions. By carefully assessing these parameters, companies can not only improve the efficiency of their production processes but also ensure that their final products meet stringent quality standards. Ultimately, making informed choices about PVC granules is essential for harnessing the full potential of this versatile material in various applications.

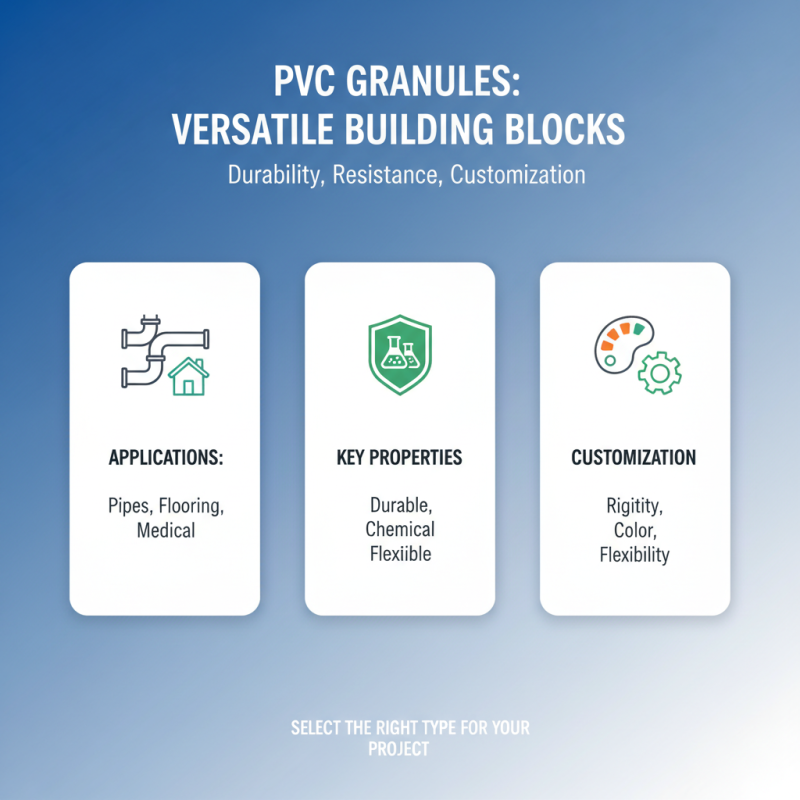

PVC granules, or polyvinyl chloride granules, are small plastic particles that serve as the fundamental building blocks for various applications, ranging from construction materials to consumer goods. Understanding the properties of PVC granules is essential for selecting the right type for specific projects. These granules are renowned for their durability, chemical resistance, and versatility, making them suitable for a wide range of applications, including pipes, flooring, and medical devices. Additionally, PVC granules can be manufactured with varying degrees of rigidity, flexibility, and color, allowing for customization based on the requirements of the project.

When evaluating PVC granules, it is crucial to consider their additives and formulation. Many granules come with stabilizers, plasticizers, and impact modifiers that enhance their performance and usability. For instance, plasticized PVC granules offer increased flexibility, making them ideal for applications requiring bending or molding. On the other hand, rigid PVC granules are often used in applications where structural integrity is paramount. Understanding these properties aids in making informed decisions that align with the specific mechanical, thermal, and chemical demands of the end product, ensuring optimal performance and longevity in its application.

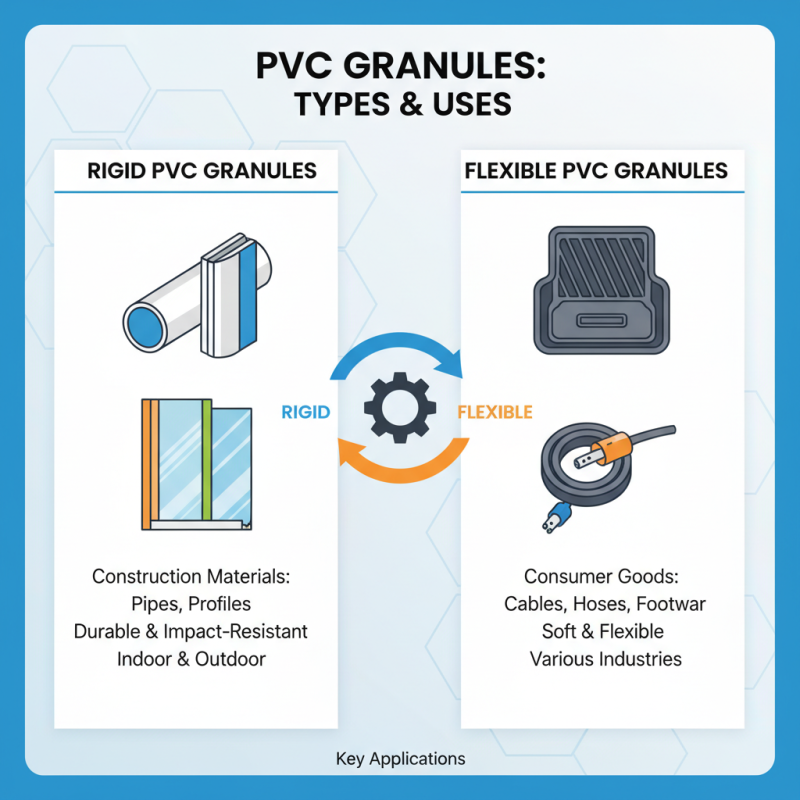

When selecting the right PVC granules for various applications, it's crucial to understand the different types available and their specific uses. One popular type is rigid PVC granules, commonly used in construction materials, such as pipes and profiles. These granules provide excellent durability and resistance to impact, making them suitable for both indoor and outdoor applications.

Another category is flexible PVC granules, which are often blended with additives to enhance their flexibility and softness. These are ideal for products like cables, flooring, and inflatable items due to their ability to withstand bending and stretching without losing integrity. Understanding the balance between rigidity and flexibility will help you choose the right granules for your project.

**Tips:** When selecting PVC granules, consider the environment where the final product will be used. For outdoor applications, ensure the granules have UV stabilizers to prevent degradation from sunlight. Additionally, review the processing methods required for each type of PVC, as some may require specific equipment or conditions to achieve optimal results. Always consult with suppliers regarding the granules' material safety data sheets (MSDS) to ensure they meet your project’s requirements.

When selecting PVC granules for your projects, several critical factors should be taken into account to ensure the best fit for your specific needs. First and foremost, you should evaluate the intended application of the granules. Different projects may require different properties, such as flexibility, rigidity, or chemical resistance. Understanding whether the final product will be exposed to harsh environmental conditions or mechanical stress can help determine the right formulation of PVC granules.

Another important aspect to consider is the granule size and consistency. The homogeneity of the granules can significantly impact the processing and final product quality. Finer granules generally lead to more uniform dispersion and mixing, while larger granules may be easier to handle and transport. Additionally, it is vital to assess the thermal stability of the granules, particularly if your project involves high-temperature processing methods. Analyzing these characteristics can guide you in selecting the most effective PVC granules for your application, ultimately enhancing the performance and durability of your finished products.

When evaluating the quality and performance of PVC granules for your projects, it is crucial to understand the factors that contribute to their effectiveness and suitability for different applications. The primary qualities to consider include thermal stability, tensile strength, and plasticizers used in the formulation. According to a recent report by Grand View Research, the global PVC market is projected to reach USD 75.3 billion by 2027, underscoring the importance of selecting high-quality granules to meet growing industry demands.

One key factor in assessing PVC granules is their processing characteristics, which affect the final product's durability and appearance. Look for granules with a uniform particle size, as this can lead to improved flow properties during extrusion or molding processes. Additionally, consider the thermal stability ratings, as granules with higher stability can withstand processing temperatures better, thereby enhancing performance under stress.

Tip: Always request samples from suppliers, allowing for hands-on testing of the granules in your specific applications. Checking for compliance with industry standards such as ASTM can also provide assurance of quality. Conducting preliminary trials can help identify the best formulation for your needs, ensuring long-term satisfaction with the final product.

When it comes to sourcing PVC granules for various applications, sustainability is increasingly becoming a key consideration. The manufacturing and disposal of PVC have raised environmental concerns, prompting many companies to seek materials that not only meet their project requirements but also adhere to sustainability standards. According to a 2022 report by the Plastics Industry Association, approximately 40% of PVC demand in the construction sector is now driven by sustainability criteria, highlighting the growing importance of selecting eco-friendly materials.

To make informed choices, it's crucial to evaluate the sourcing practices of PVC granule suppliers. Look for those that utilize post-consumer recycled PVC or those that adhere to responsible sourcing practices that minimize environmental impact. The Sustainable Materials Rating Technology (SMaRT) certification system is an excellent tool for assessing the sustainability credentials of PVC products, providing transparency about the lifecycle impacts of materials. Furthermore, a study in 2023 indicated that sustainable PVC options could reduce carbon footprints by up to 30% compared to traditional PVC, showcasing the potential benefits of prioritizing sustainability in material selection.

Moreover, while assessing the overall sustainability of PVC granules, consider factors such as energy consumption during production and the end-of-life recyclability of the material. An analysis from the International Plastic Waste Association suggests that products made from recycled PVC can significantly lower greenhouse gas emissions, reinforcing the idea that selection goes beyond immediate project needs but should also encompass future ecological impacts. By choosing PVC granules with sustainable sourcing practices, companies can contribute to a more circular economy and align with global sustainability goals.

This chart illustrates the suitability of different types of PVC granules for various applications, rated on a scale from 1 to 10. General Purpose and Impact-Resistant granules score the highest, making them ideal for a wide range of projects.