Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

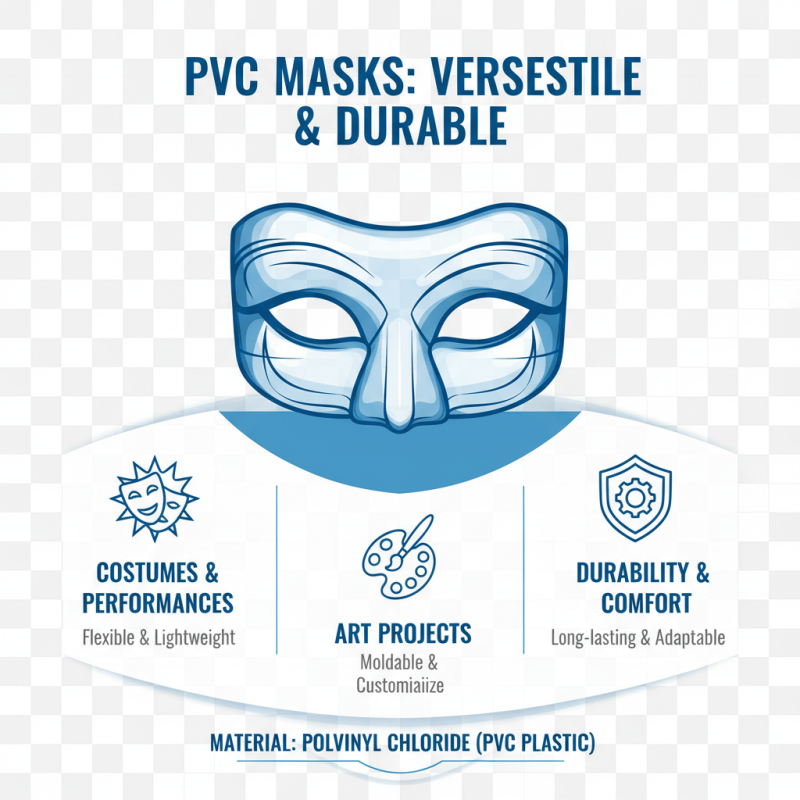

PVC masks have gained significant attention in various industries. This is mainly because of their versatility and effectiveness in multiple applications. According to a recent report by ResearchAndMarkets, the global market for PVC products is projected to reach $73 billion by 2026. Among these products, PVC masks stand out for their unique properties.

These masks are not just protective gear; they are widely used in arts, crafts, and special effects. Their flexible nature allows for intricate designs, enhancing their aesthetic appeal. Many artists and professionals favor PVC masks for their durability and ease of use. However, the manufacturing process raises concerns about environmental impacts. The production of PVC can release harmful chemicals, which cannot be overlooked.

Furthermore, while PVC masks provide benefits, they also have limitations. For instance, prolonged use may lead to discomfort. Awareness of proper usage and maintenance is crucial. The balance between creativity and sustainability remains a topic of debate in the industry. As such, understanding the full scope of PVC masks is vital for informed choices.

PVC masks are versatile tools used in various applications. These masks are made from polyvinyl chloride, a durable plastic material. When heated, PVC can be molded into different shapes. This property makes it an ideal choice for creating masks with intricate designs. PVC masks are often lightweight and easy to wear, making them popular for costume parties and theatrical performances.

One of the unique aspects of PVC masks is their ability to capture detailed facial features. Artists can create realistic expressions and designs. This adds depth to costumes and enhances the overall experience. However, not every PVC mask fits perfectly. Some may feel uncomfortable or restrict movement. Users often need to adjust them for a better fit. This can be a trial-and-error process, highlighting the need for careful selection.

Additionally, while PVC masks can be striking in appearance, they may not be breathable. This can lead to discomfort during long wear. It's essential to consider the purpose of the mask before use. Whether for art, performance, or another reason, understanding one's needs is vital. Not every mask will meet expectations, and reflection on comfort and usability is necessary for an enjoyable experience.

PVC masks are popular for various uses, including costumes, performances, and art projects. These masks are made primarily from polyvinyl chloride, a versatile plastic known for its durability and flexibility. The choice of material greatly influences the mask’s comfort and lifespan.

Common materials used in PVC masks include a blend of foam, paint, and elastic straps. The foam lining provides cushioning, making the mask easier to wear for long periods. Bright, vivid paints are often used to enhance visual appeal. The elastic straps ensure a snug fit, allowing for movement without fear of the mask slipping. However, the combination of these materials can sometimes create imperfections. Bubbles in the surface or uneven paint can occur during production.

Many creators strive for perfection. Yet, some find beauty in the flaws. A small dent or an asymmetrical design can add character. It invites viewers to reflect on the artistry involved. Ultimately, the choice of materials directly affects not only the aesthetics but also the function of the mask in various contexts.

PVC masks have gained traction across various industries due to their versatile applications. In healthcare, they serve as protective barriers. These masks prevent the spread of germs. They are lightweight and easy to clean. Healthcare providers often use them during procedures.

In the entertainment industry, PVC masks provide unique costume solutions. They come in various designs and can be customized. Artists use them for theatrical performances and events. The masks can enhance character portrayal. However, the comfort level may vary for different users. It’s important to consider breathability, especially during long wear.

Manufacturers should reflect on production processes. Overuse of PVC can raise environmental concerns. Exploring sustainable alternatives can be valuable. Some masks also lack proper fitting. This can lead to discomfort and inefficiency. Awareness of these factors can drive improvements in future designs.

PVC masks are popular in various applications, from costume parties to professional performances. To ensure a long-lasting and enjoyable experience, proper use and maintenance are essential. When handling a PVC mask, always check for any signs of wear or damage. This prevents discomfort during use and ensures you won’t accidentally break it.

Cleaning your PVC mask is straightforward. Use a damp cloth with mild soap. Avoid harsh chemicals as they can degrade the material. After cleaning, let the mask air dry. Never use heat sources to dry it, as this can warp the shape. Proper storage is equally crucial. Store the mask in a cool, dry place. Keep it away from direct sunlight to prevent fading.

**Tips:** Regular inspections can save masks from early wear. Always test makeup products on a small area before full application. And remember, if the mask feels tight or uncomfortable, it might not fit correctly. Adjustments can make a big difference. Taking these steps keeps your mask looking great and functional!

PVC masks are commonly used for various applications, including theater productions and protective gear. Understanding safety considerations is crucial for users. PVC material can cause skin irritation in some cases. It is essential to check for allergies before usage.

Regulations surrounding PVC mask production are strict. Masks should meet specific safety standards. Users should always read and follow guidelines. Proper ventilation during usage is vital. Prolonged exposure can lead to respiratory issues. It’s necessary to have breaks to avoid discomfort.

Mold is a real concern with these masks. Regular cleaning reduces risks. Storing masks in dry places helps maintain quality. However, some users might overlook these details. Taking time to ensure proper maintenance is critical for safety. Overall, awareness of these considerations can greatly enhance the user experience.