Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

PVC sheets are versatile plastic materials that play a crucial role across various industries, including construction, healthcare, and advertising. According to industry expert Dr. Emily Johnson, a renowned materials scientist, "PVC sheets are valued not only for their durability but also for their adaptability in multiple applications." This statement encapsulates the essence of PVC sheets, highlighting their significance in modern manufacturing and design.

In the construction industry, PVC sheets are frequently utilized for cladding, flooring, and roofing solutions due to their lightweight nature and resistance to weathering. In healthcare, they provide a reliable solution for protective barriers, ensuring sanitary environments in medical facilities. Furthermore, in the advertising sector, PVC sheets serve as an effective medium for signage and displays, enabling vibrant and eye-catching presentations.

As the demand for sustainable and cost-effective materials grows, understanding the properties and applications of PVC sheets becomes increasingly important. The ability to customize these sheets for specific uses makes them a staple in countless applications. Thus, exploring the many facets of PVC sheets and their implications in various sectors reveals their indispensable role in contemporary industry.

PVC sheet, or polyvinyl chloride sheet, is a versatile and widely used material in various industries due to its favorable properties. It is a synthetic plastic polymer that is known for its durability, chemical resistance, and ease of fabrication. According to a report from Research and Markets, the global PVC sheet market was valued at approximately $7.5 billion in 2020 and is projected to grow at a CAGR of 5.3% from 2021 to 2026. This growth is attributed to its extensive applications in construction, automotive, packaging, and electrical industries.

In the construction sector, PVC sheets are commonly used for window frames, roofing membranes, and cladding due to their excellent weather resistance and thermal insulation properties. The demand for PVC in construction is driven by the increasing focus on sustainable building practices. For example, PVC sheets can be recycled, contributing to more eco-friendly construction solutions.

Additionally, in the automotive industry, PVC sheets are utilized for interior panels and dashboards because of their lightweight nature and aesthetic flexibility, catering to modern design trends.

Furthermore, PVC sheets are also prevalent in the packaging industry, where they are utilized for creating rigid packaging solutions. The material’s transparency, combined with its lightweight and cost-effectiveness, makes it an ideal choice for manufacturers looking to reduce costs while maintaining product visibility. According to Statista, the demand for plastic packaging is expected to reach approximately 400 million metric tons by 2025, further solidifying the role of PVC sheets in this growing market.

PVC (Polyvinyl Chloride) sheets are versatile materials derived from the polymerization of vinyl chloride monomers. Their composition typically includes a blend of additives to enhance properties such as durability, flexibility, and fire resistance. PVC sheets can be manufactured in various thicknesses and textures, allowing them to be tailored for specific applications. Common characteristics include moisture resistance, chemical stability, and an excellent balance of rigidity and flexibility, making them suitable for a range of environments.

In various industries, PVC sheets serve multiple functions. In construction, they are used for cladding, roofing membranes, and window profiles due to their weather-resistant properties. The automotive sector values PVC sheets for interior components, while the medical field uses them for protective barriers and medical packaging. Additionally, PVC sheets are popular in signage and display applications because of their ease of printing and cutting.

Tips: When selecting PVC sheets for your project, consider the specific environmental conditions they will face, such as exposure to sunlight or chemicals. This can significantly affect the longevity and performance of the material. Always check for compliance with industry standards to ensure safety and functionality in your application.

PVC sheets, known for their versatility and durability, find extensive applications across various industries. In the construction sector, they are utilized as siding, roofing materials, and window frames due to their weather resistance and insulation properties. According to a report by Global Industry Analysts, the increasing demand for lightweight and low-cost materials in construction has propelled the PVC market, with growth projected at a compound annual growth rate (CAGR) of 6.8% through 2025.

The healthcare industry also leverages PVC sheets for manufacturing medical equipment, packaging, and disposable items such as syringes and IV bags. Their ability to be sterilized and resistance to chemicals make them ideal for these applications. A study published in the Journal of Applied Polymer Science indicated that PVC is expected to maintain a significant presence in the healthcare market, driven by advancements in medical technology and rising healthcare expenditures.

Tips: When working with PVC sheets, consider using proper cutting tools to avoid jagged edges, which can compromise safety and aesthetics. Additionally, ensure that the environment where PVC is stored and used is well-ventilated to avoid the accumulation of fumes during installation and application.

PVC sheets, or polyvinyl chloride sheets, are widely embraced across various industries due to their remarkable advantages over other materials. One of the critical benefits is their exceptional durability. According to a report by MarketsandMarkets, the global PVC market is projected to reach $81.7 billion by 2025, driven by a growing demand for durable and cost-effective materials. PVC sheets are resistant to moisture, chemicals, and corrosion, making them ideal for applications in construction, signage, and packaging.

Another significant advantage is the lightweight nature of PVC sheets, which simplifies handling and reduces shipping costs. This can lead to significant savings for manufacturers and businesses. Additionally, PVC is easily fabricated and can be produced in various colors and thicknesses, allowing for customization that meets specific project requirements. A recent study highlighted that industries utilizing PVC sheets have reported up to a 30% reduction in operational costs due to their versatility and ease of installation.

Tips: When selecting PVC sheets for a project, consider the specific environmental conditions they will face. For instance, UV-resistant options are recommended for outdoor applications to ensure longevity. Furthermore, always ensure compliance with industry standards to guarantee safety and performance, as regulations may vary across different sectors.

| Property | PVC Sheets | Other Materials |

|---|---|---|

| Weight | Lightweight | Heavy (e.g., metal) |

| Cost | Cost-effective | More expensive |

| Durability | Highly durable | Varies |

| Chemical Resistance | Excellent | Limited |

| Weather Resistance | Good | Varies |

| Applications | Signage, construction, packaging | Furniture, machinery |

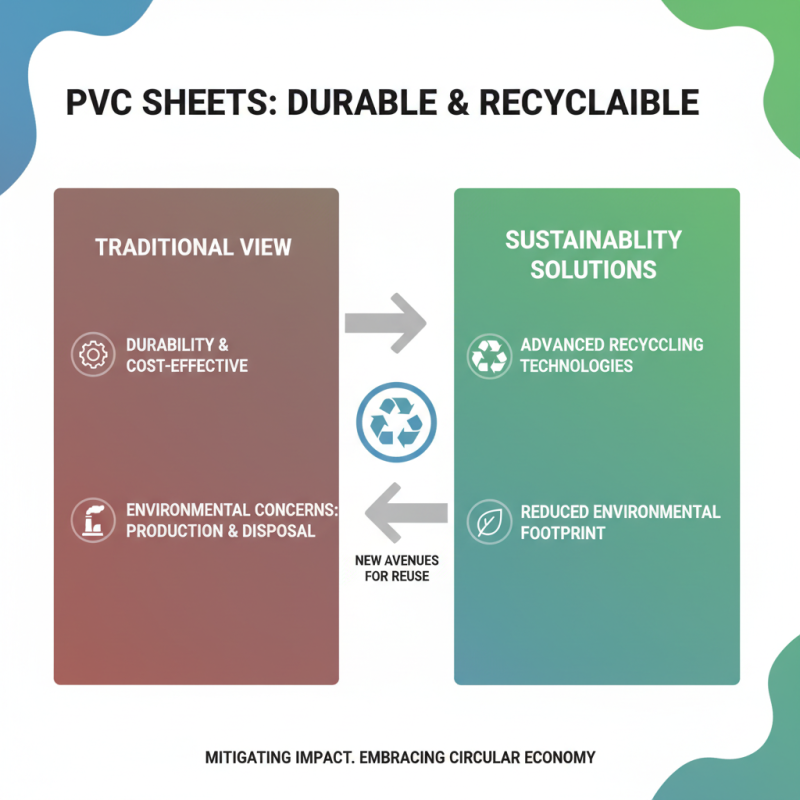

PVC sheets are versatile materials widely used across various industries due to their durability and cost-effectiveness. However, the environmental impact of PVC production and disposal has led to increasing scrutiny regarding sustainability practices. Fortunately, advancements in recycling technologies have opened new avenues for reusing PVC sheets, significantly mitigating their environmental footprint.

Recycling PVC sheets not only helps in reducing waste but also conserves natural resources. The process typically involves collecting discarded PVC products, processing them into pellets, and then remanufacturing those pellets into new sheets or other products. This closed-loop system can reduce the demand for virgin raw materials and lower energy costs associated with production. Additionally, innovative practices, such as using recycled PVC in construction and automotive applications, highlight the growing recognition of PVC's potential in sustainable development.

Moreover, many industries are now prioritizing the use of recycled materials in their operations. By utilizing PVC sheets made from recycled content, companies can enhance their sustainability credentials while meeting regulatory requirements and consumer demands for environmentally friendly products. The emphasis on responsible sourcing and recycling demonstrates a commitment to reducing the overall ecological impact associated with PVC, making it a more sustainable option in various applications.