High-Quality Clear Thin Plastic from Reliable China Suppliers - Quality Assured

Jiangsu Dahai Plastics Co., Ltd. is a distinguished manufacturer of high-quality clear thin plastic, renowned for its reliable and superior products. Our clear thin plastic is engineered for versatility, durability, and clarity, making it ideal for a wide range of applications including packaging and protection. With a commitment to precision in production, we meet the diverse needs of various industries effectively.Key Methods For Clear Thin Plastic Products Service

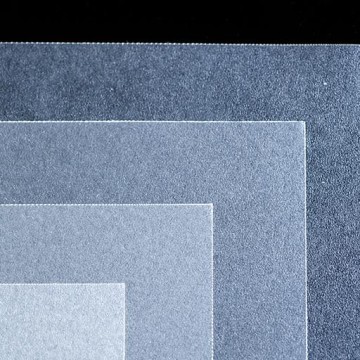

When it comes to sourcing clear thin plastic products, understanding the key methods for ensuring quality and performance can significantly impact your production and supply chain. The first essential method is selecting the right type of material. Clear PVC Film is widely used across various industries due to its exceptional transparency, durability, and versatility. This type of film can be tailored to meet specific needs, whether for packaging, protective coverings, or even specialized applications like toys and bath products. By choosing the correct film type, buyers can enhance product visibility while ensuring safety and compliance with industry standards. Another important method is focusing on the manufacturing process and technology involved in producing these films. Advanced printing techniques and high-quality production methods are crucial in achieving not only visual appeal but also functional performance. Working with manufacturers that utilize cutting-edge technology guarantees that the final products will meet stringent quality control measures, which can reduce the likelihood of defects and improve the overall user experience. Effective collaboration with suppliers can also facilitate customization options, empowering buyers to create distinctive products that stand out in the competitive market. Lastly, building strong communication channels and partnerships with suppliers can streamline logistics and improve service reliability. By establishing clear expectations regarding delivery timelines, order quantities, and quality standards, procurement teams can better manage their supply chain and ensure that their sourcing needs are consistently met. Emphasizing transparency and responsiveness fosters long-term relationships, ultimately leading to better pricing models and improved service quality. These key methods collectively help businesses navigate the complexities of sourcing clear thin plastic products, leading to enhanced operational efficiency and customer satisfaction.

Key Methods For Clear Thin Plastic Products Service

| Method | Description | Advantages | Applications |

|---|---|---|---|

| Injection Molding | A manufacturing process for producing parts by injecting material into a mold. | High efficiency, ability to create complex shapes, minimal waste. | Bottles, containers, and electronic housings. |

| Thermoforming | A process where plastic is heated and formed over a mold to create a shape. | Cost-effective for short runs, good for large parts and deep shapes. | Packaging, trays, and automotive components. |

| Blow Molding | A process for forming hollow plastic parts by blowing air into heated plastic. | Fast production rates, efficient for hollow shapes. | Bottles and other similar containers. |

| 3D Printing | A method of creating three-dimensional objects layer by layer using a digital model. | Customization, reduced lead time, flexibility in designs. | Prototyping, small batch production, and intricate designs. |

Smart Ways To Clear Thin Plastic Guarantees Peak Performance Exceeds Industry Benchmarks

E

Emily Carter

The product exceeded my expectations in terms of quality. Moreover, the after-sale service was top-notch and very supportive.

26 June 2025

L

Logan Wilson

I absolutely love the quality! The professionalism of the service team was exemplary.

22 June 2025

O

Owen Harris

Impressive quality product! Their service team was attentive and solved my issues swiftly.

30 June 2025

C

Caleb Carter

Great product! The support staff provided clear and professional guidance.

30 June 2025

S

Sarah Wilson

Impressive quality! Their professional after-sale service team made all the difference.

15 June 2025

O

Oliver Brown

Great quality! The service staff were well-informed and handled my request expertly.

08 May 2025