Top Eva Film Manufacturing Processes: Leading Manufacturers & Factories Outline

For high-quality EVA film, finding trustworthy manufacturers is essential. At Jiangsu Dahai Plastics Co., Ltd., we leverage advanced technology to ensure every batch meets the rigorous standards of our B2B partners. Our dedicated team oversees the entire manufacturing process, from production to final quality checks, guaranteeing durable products tailored to your specifications. With a strong emphasis on customer satisfaction, we strive to cultivate lasting partnerships. Contact us to learn more about how our manufacturing expertise can enhance your projects.

7 Key Tips To Eva Film Manufacturing Process For the Current Year Manufacturer

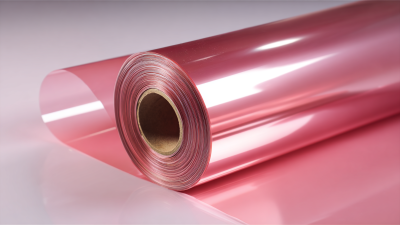

When it comes to manufacturing PVC Film, understanding the key aspects of the production process is crucial for global buyers looking for high-quality materials that cater to diverse applications. The evolving demands of various industries require manufacturers to streamline their processes while ensuring excellence in the final product. Here are seven key tips to enhance the PVC film manufacturing process and meet current market needs effectively. Firstly, choosing the right raw materials significantly influences the quality of the final film. Sourcing high-grade PVC resin ensures better durability and transparency, which are essential for applications such as packaging and protective films. Secondly, investing in advanced technology and equipment is vital. Automated processes not only increase efficiency but also minimize human error, leading to consistent product quality. Thirdly, conducting thorough quality control checks at every production stage helps in identifying issues early on, ensuring that only the best products reach the market. Moreover, staying adaptable to market trends is essential for manufacturers. Regularly updating production techniques, exploring new formulations, and introducing innovative products can give manufacturers a competitive edge. Finally, fostering strong relationships with suppliers and distributors is crucial. Effective collaboration can lead to better supply chain management, increased responsiveness to customer needs, and ultimately, a stronger market presence. By implementing these strategies, manufacturers can optimize their PVC film production to meet the demands of today and beyond.

7 Key Tips To Eva Film Manufacturing Process For the Current Year Manufacturer

| Tip No. | Key Tip | Description | Expected Outcome |

|---|---|---|---|

| 1 | Optimize Material Selection | Choose high-quality EVA materials specific to application needs. | Improved product performance and durability. |

| 2 | Invest in Efficient Machinery | Utilize modern machinery to enhance production speed and accuracy. | Reduced operational costs and lead times. |

| 3 | Implement Quality Control Measures | Establish a rigorous QC process throughout production. | Consistency in product quality and reduced waste. |

| 4 | Enhance Employee Training | Provide ongoing training for staff on new technologies and safety protocols. | Increased workforce efficiency and safety compliance. |

| 5 | Utilize Data Analytics | Leverage analytics to monitor production metrics and optimize processes. | Better decision-making and proactive issue resolution. |

| 6 | Focus on Sustainability | Incorporate eco-friendly practices in manufacturing processes. | Reduced environmental impact and improved brand reputation. |

| 7 | Stay Updated with Industry Trends | Regularly review market trends and adapt to the changing landscape. | Enhanced competitiveness and innovation in product offerings. |

Where the Value Lies Eva Film Manufacturing Process Exceeds Industry Benchmarks Service

H

Henry Lopez

Impressive quality! The customer support was reliable, addressing all my concerns.

14 May 2025

L

Lucy Thompson

Absolutely love the quality! The after-sale service was reliable and very informative.

11 May 2025

L

Logan Wilson

I absolutely love the quality! The professionalism of the service team was exemplary.

22 June 2025

M

Matthew Johnson

Incredible quality! The professionalism in their service team was impressive.

09 June 2025

C

Chloe Harris

Outstanding quality! Their support staff were professional and very quick to help.

10 May 2025

L

Lily Jones

High quality! The professionalism exhibited by the support staff made the experience enjoyable.

28 June 2025