In recent years, demand for polyvinyl chloride (PVC) film has surged across various industries due to its versatility, durability, and affordability. PVC film, especially Rigid Film, is widely used in packaging, medical supplies, construction, and consumer goods. This article will explore different types of PVC film, including PVC granules, rigid PVC film, PVC abrasion layers, and their alternatives, such as polyethylene (PE), ethylene-vinyl acetate copolymer (EVA), and polyethylene-vinyl acetate copolymer (PEVA) films. We will also analyze the product applications and market demand for these materials in detail.

Understanding PVC Film

PVC film is made from PVC granules through extrusion or calendering to form sheets. Depending on the formulation and additives, these films can be rigid or flexible. Rigid PVC film is popular due to its high strength and resistance to deformation, making it ideal for a wide range of applications.

📌 Pvc Rigid Film:

This type of film is characterized by its stiffness and is commonly used in packaging, signage, and building materials. Its excellent barrier properties make it suitable for protecting products from moisture, dust, and other environmental factors.

🛡️ PVC Abrasion Layer:

A PVC abrasion layer is commonly used in flooring installation. It provides a protective layer, enhancing the floor's durability and resistance to scratches and stains. This feature is crucial in high-traffic areas where floors are prone to wear and tear.

Alternative Films: PE, EVA and PEVA

Although PVC film dominates the market, alternatives such as PE, EVA and PEVA films are becoming increasingly popular due to their unique properties.

🔷 PE Film

Polyethylene film is known for its flexibility and moisture resistance. Because it can form an airtight seal, it is widely used in the packaging industry, including food packaging.

🔶 EVA Film

Ethylene-vinyl acetate copolymer films are known for their transparency and flexibility. They are commonly used in applications requiring transparency, such as the production of solar panels and adhesive films.

💚 PEVA Film

PEVA film is a mixture of polyethylene and vinyl acetate, often marketed as a safer alternative to PVC. It is commonly used in shower curtains, clothing, and other consumer products requiring non-toxic materials.

Product Application

PVC film has a wide range of applications, demonstrating its adaptability to different industries:

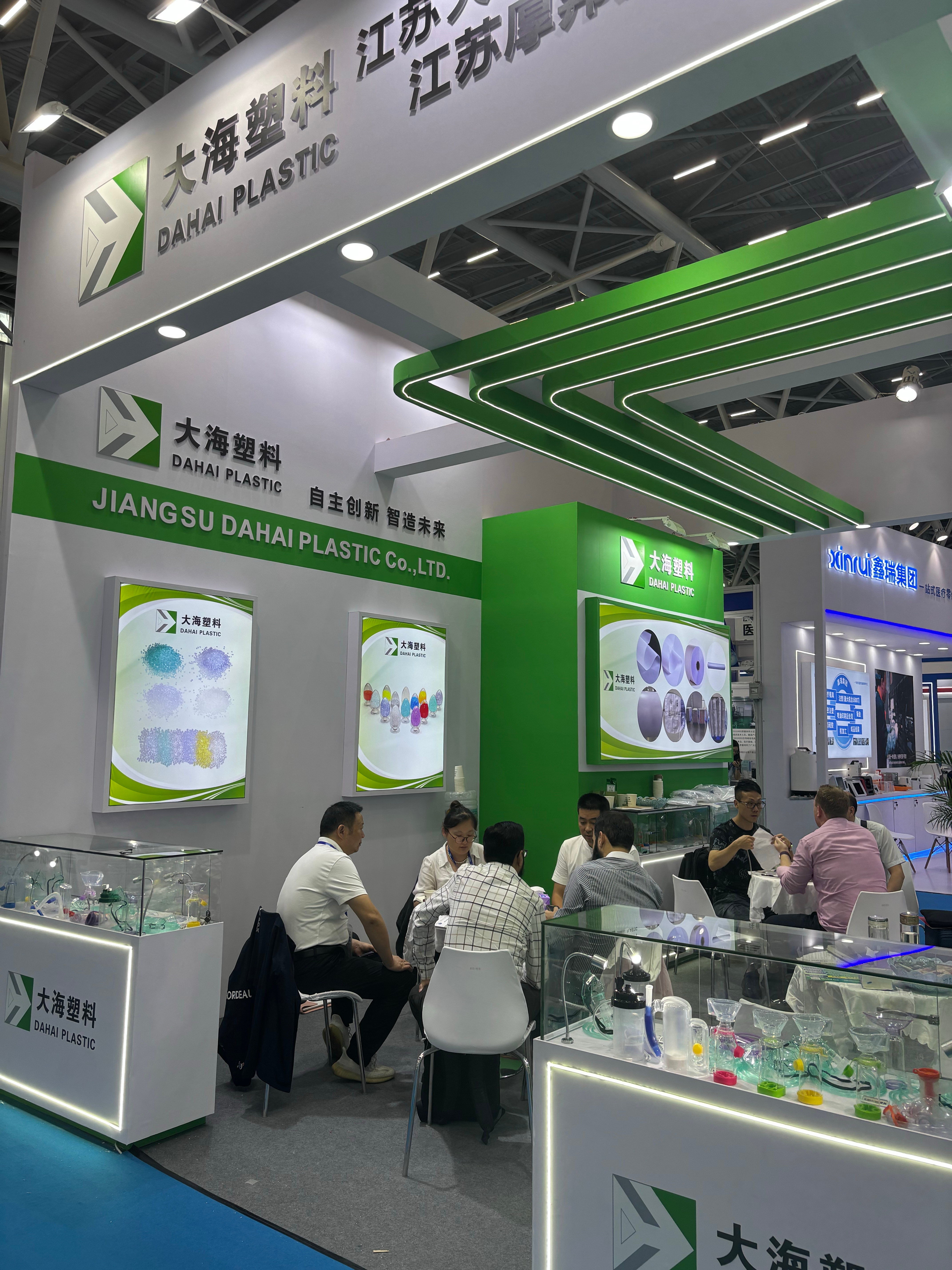

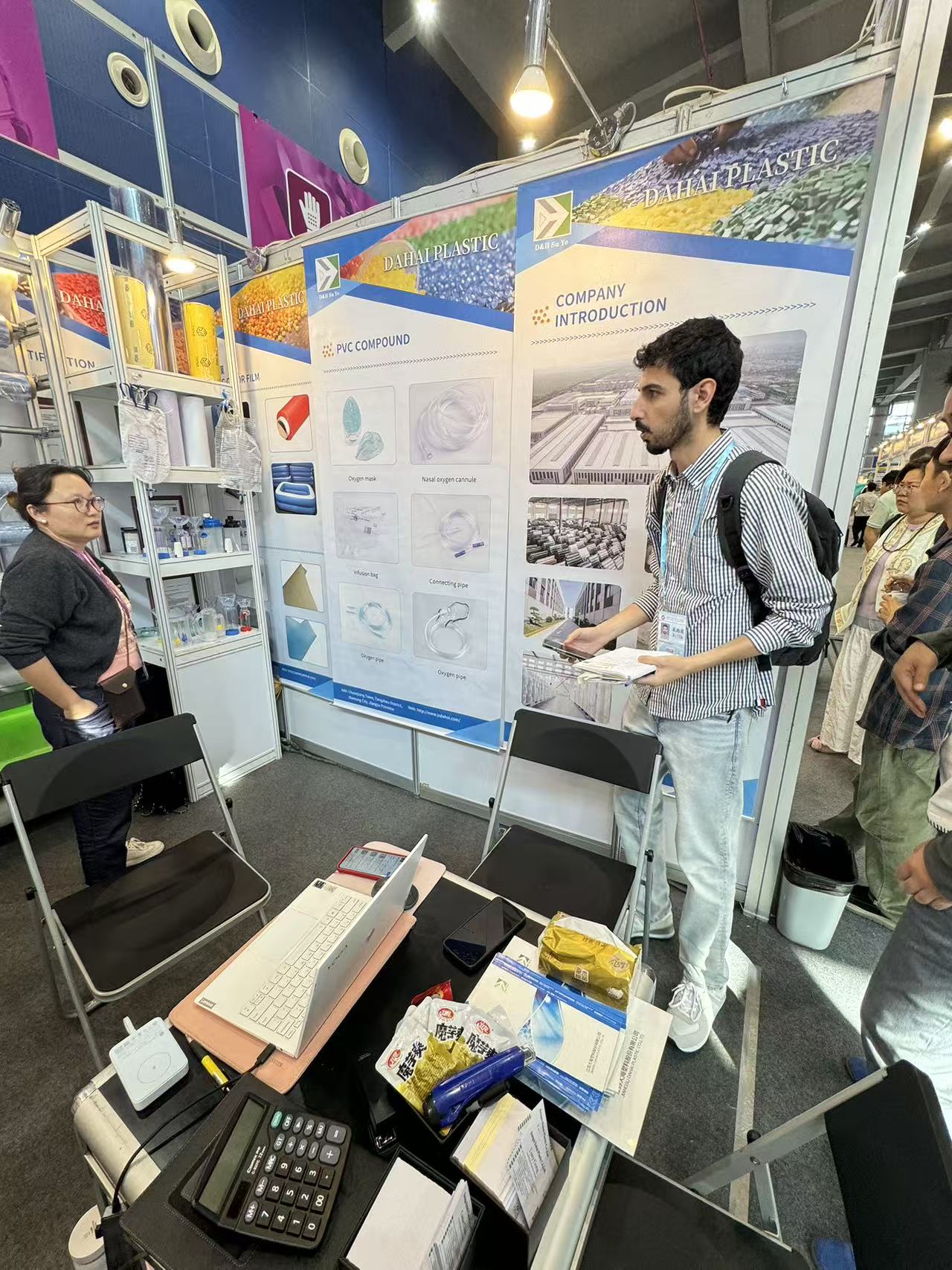

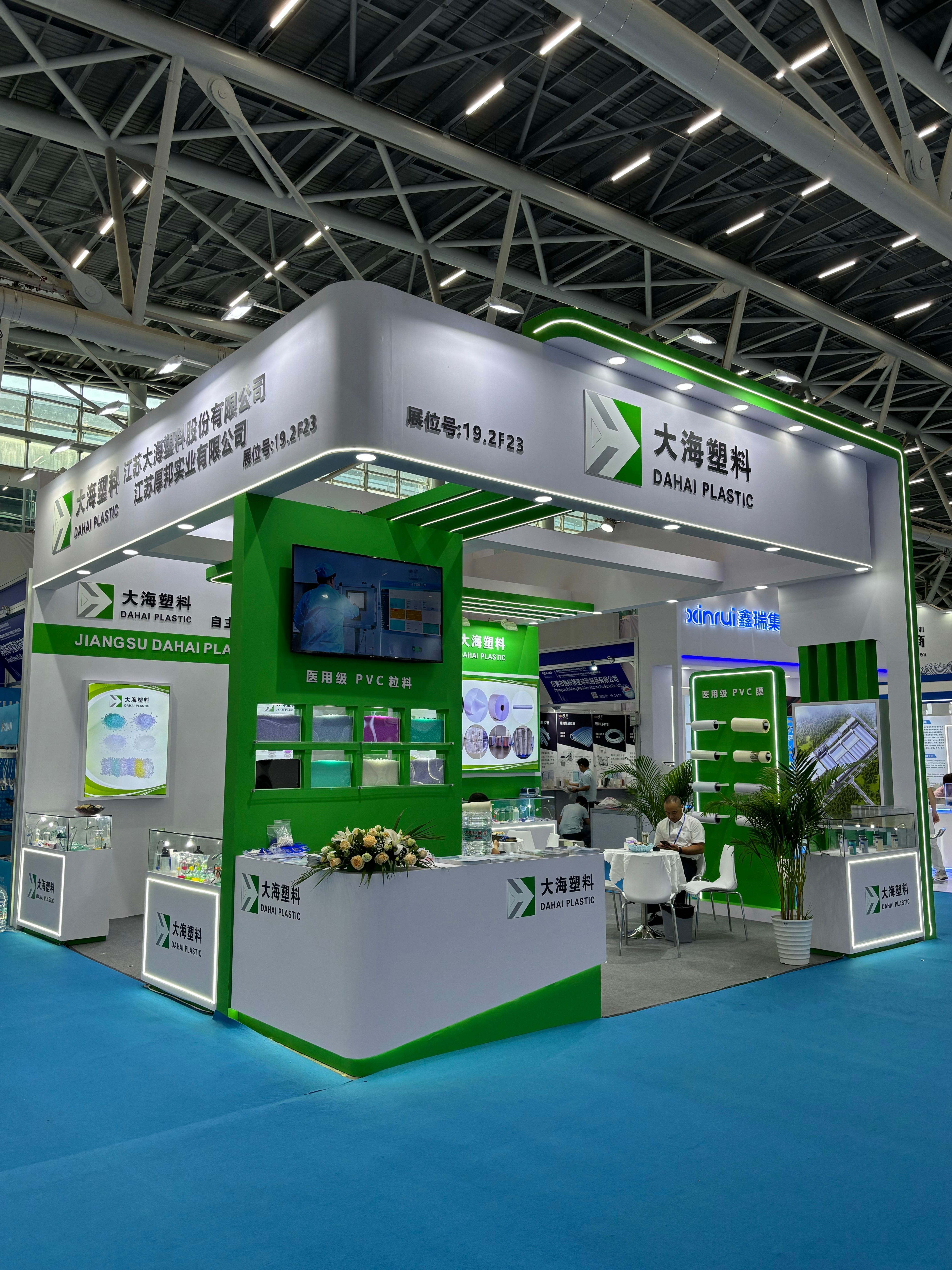

Medical Applications

PVC film is widely used in the medical field for packaging sterile products, such as surgical instruments and medical devices. Its excellent sealing properties ensure that these products remain sterile before use. In addition, PVC film is also used to produce infusion bags and tubing, products that require extremely high flexibility and durability.

Packaging

The packaging industry is one of the largest consumer sectors of PVC film. Rigid PVC film is widely used in blister packaging, bubble wrap, and shrink packaging. Its excellent barrier properties help maintain food freshness and protect consumer goods during transportation.

Construction Industry

In the construction sector, PVC film is widely used in door and window profiles, roofing membranes, and flooring. PVC's durability and weather resistance make it ideal for outdoor applications.

Consumer Goods

PVC film is also widely used in various consumer goods, including toys, stationery, and household items. Its versatility allows manufacturers to produce a wide variety of products to meet consumer demands for quality and price.

Automotive Industry

The automotive industry uses PVC film for both interior and exterior car trim, including dashboards, door panels, and seat covers. The material's resistance to UV rays and chemical corrosion makes it suitable for the automotive environment.

Market Demand

The market demand for PVC film is influenced by a variety of factors, including technological advancements, regulatory changes, and consumer preferences. The global pursuit of sustainable materials has fueled growing interest in alternatives such as PE, EVA, and PEVA films. However, PVC remains a popular choice due to its cost-effectiveness and superior performance.

The healthcare industry's growth, particularly during the COVID-19 pandemic, has significantly increased demand for PVC film. As healthcare institutions prioritize hygiene and safety, the need for reliable packaging solutions has also surged.

Furthermore, the packaging industry is constantly evolving and placing increasing emphasis on sustainability. Manufacturers are exploring methods to produce recyclable or recycled PVC films in line with global sustainability goals.

In Conclusion

Demand for PVC films, including rigid films, abrasion-resistant layers, and their alternatives, is expected to continue growing across industries. As manufacturers strive to meet the diverse needs of consumers and businesses, the versatility of PVC films will play a key role in shaping the future of the packaging, medical supplies, construction, and consumer goods industries. Driven by continuous innovation and a focus on sustainability, the PVC film market is poised for significant growth in the coming years.