Top Plastic Manufacturing Processes, Suppliers, & Leading Manufacturers for Quality Solutions

In the realm of plastic manufacturing, selecting the right supplier makes all the difference. My experience with Jiangsu Dahai Plastics Co., Ltd. has been exceptional. As a reputable manufacturer, they deliver top-notch solutions to satisfy a variety of industry demands. From Injection Molding to blow molding and extrusion, their industry expertise is unparalleled. Their dedication to innovation and commitment to quality assurance truly distinguishes them from competitors. With a solid reputation built over years, they offer not just products but also insights into the latest trends in plastic manufacturing. For those seeking a reliable partner to enhance production processes and meet specific requirements, Jiangsu Dahai Plastics stands out as a commendable choice. You won't be disappointed!Top Picks For Plastic Manufacturing Processes Dominates From Concept to Delivery

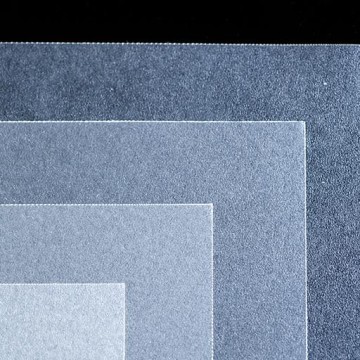

In today's fast-paced manufacturing landscape, efficiency and innovation are paramount. At Jiangsu Dahai Plastics Co., Ltd., we understand the intricacies involved in plastic manufacturing processes, from initial concept to final delivery. Established in 1996, we have carved a niche as a leader in producing high-quality Pvc Films, including super transparent films, toy films, bath films, and more. Our expertise in printing PVC film technology sets us apart, enabling us to cater to a diverse range of applications and industries. Our commitment to excellence ensures that we utilize advanced manufacturing techniques and quality materials, resulting in products that meet international standards. We recognize that our global clients require solutions that not only fulfill their specific needs but also offer reliability and durability. We prioritize customer satisfaction, working closely with clients to tailor our offerings to fit their unique specifications, thus fostering long-term relationships built on trust and quality. As we navigate the evolving challenges of the plastic manufacturing sector, our focus remains unwavering on delivering innovative solutions and maintaining exceptional quality control processes. Whether you seek standard products or custom solutions, Jiangsu Dahai Plastics Co., Ltd. stands ready to be your partner in success, ensuring that your concepts transition seamlessly into delivery. Reach out to us for unparalleled expertise and reliable service in the world of PVC films.

Top Picks For Plastic Manufacturing Processes Dominates From Concept to Delivery

| Process Type | Description | Applications | Advantages | Typical Lead Time |

|---|---|---|---|---|

| Injection Molding | A process to create parts by injecting molten material into a mold. | Automotive parts, consumer goods, medical devices. | High efficiency, ability to produce complex shapes, low production costs. | 2 to 6 weeks |

| Blow Molding | A method for forming hollow plastic parts using air pressure. | Bottles, tanks, and other hollow objects. | Cost-effective for high volume, produces lightweight objects. | 3 to 8 weeks |

| Thermoforming | A process to heat a plastic sheet and form it over a mold. | Packaging, automotive interiors, trays. | Versatile, quick setup, cost-effective for short runs. | 1 to 4 weeks |

| Rotational Molding | A method where plastic is heated and rotated to form a hollow product. | Toys, large containers, outdoor equipment. | Good for large parts, low stress on material, cost-effective. | 4 to 10 weeks |

| Extrusion | The process of shaping materials by forcing them through a die. | Pipes, sheets, and films. | Continuous production, high-volume efficiency. | 2 to 6 weeks |

Best Way To Plastic Manufacturing Processes Guarantees Peak Performance Pioneers in the Field

L

Lucas Martinez

Fantastic quality! The after-sale service was swift and very courteous.

20 June 2025

B

Benjamin Lee

The product quality is simply amazing, and their customer care was outstanding.

19 June 2025

C

Carter Ramirez

Absolutely outstanding quality! Their customer service was highly effective and professional.

14 June 2025

C

Chloe Turner

The quality is top-notch! The after-sale service proved to be incredibly reliable and professional.

27 May 2025

O

Olivia Brown

Absolutely love the quality! The customer support was attentive and trustworthy.

19 May 2025

D

Daniel Patel

Impressive quality! The support team’s expertise made my experience much easier.

21 June 2025