Top China Suppliers for Plastic Manufacturing Techniques: Trusted Manufacturers & Insights

At Jiangsu Dahai Plastics Co., Ltd., we specialize in high-quality plastic manufacturing solutions tailored to your specific requirements. Our advanced processes and state-of-the-art machinery ensure that every product meets the highest quality standards. With a team of skilled professionals dedicated to manufacturing excellence, we understand the complexities of Plastic Production. Our versatility allows us to serve various industries, whether you need custom components or bulk orders. Partnering with us guarantees a commitment to quality and efficiency that distinguishes us in the market. Choose Jiangsu Dahai Plastics Co., Ltd. for exceptional plastic manufacturing that realizes your vision with durable products built to last.

Top Picks For Plastic Manufacturing Techniques Where Service Meets Innovation Pioneers in the Field

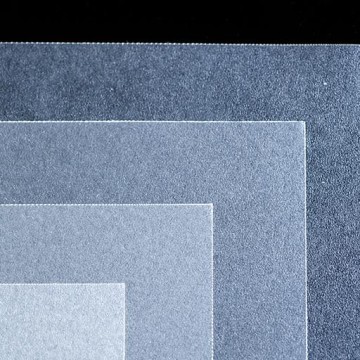

At Jiangsu Dahai Plastics Co., Ltd., we understand that innovation is the cornerstone of success in the plastic manufacturing industry. Established in 1996, our expertise lies in producing a diverse range of PVC films, including super transparent film, ordinary transparent film, toy film, bath film, raincoat film, and electrical taPe Film. As we strive to be at the forefront of plastic manufacturing techniques, our commitment to quality and service has earned us a reputation as pioneers in the field. Our plastic manufacturing processes integrate advanced technology with sustainable practices, ensuring efficiency without compromising environmental responsibility. By utilizing cutting-edge production techniques and high-grade materials, we deliver products that meet the highest industry standards. Our super transparent films are not only ideal for packaging but also provide unmatched clarity and durability, making them a preferred choice for global clients. As a partner to our customers worldwide, we emphasize collaboration and innovation to tailor our products to meet specific market needs. Whether you are looking for custom solutions or ready-to-use films, Dahai Plastics is dedicated to serving you with exceptional quality and unmatched service. Together, let’s reshape the future of plastic manufacturing, where service meets innovation.

Top Picks For Plastic Manufacturing Techniques Where Service Meets Innovation Pioneers in the Field

| Technique | Description | Advantages | Applications |

|---|---|---|---|

| Injection Molding | A manufacturing process for producing parts by injecting molten material into a mold. | High efficiency, precision, and ability to create complex shapes. | Automotive parts, consumer goods, and medical devices. |

| 3D Printing | A process of making three-dimensional solid objects from a digital file. | Customizability, reduced waste, and rapid prototyping. | Prototyping, tooling, and complex geometries. |

| Blow Molding | A manufacturing process that forms hollow plastic parts by inflating a heated plastic tube inside a mold. | Efficient for producing large volumes of hollow parts. | Bottles, containers, and automotive fuel tanks. |

| Thermoforming | A process that involves heating a plastic sheet until it's pliable, then forming it over a mold. | Cost-effective for low-volume production. | Packaging, point-of-sale displays, and medical trays. |

| Rotational Molding | A manufacturing process for creating hollow parts by rotating a mold filled with powdered plastic. | Versatility in design and durability of end products. | Large storage tanks, playground equipment, and automotive parts. |

How-To Guide Plastic Manufacturing Techniques Is The Best Outperforms the Competition

S

Sophia Thompson

The quality is unmatched! The support staff was incredibly helpful throughout the process.

23 May 2025

J

Jackson Hall

Great quality! The customer service team was responsive and knowledgeable.

11 June 2025

H

Hailey Walker

I truly appreciate the high quality! The service team is skilled and attentive.

08 June 2025

A

Aiden Lee

Quality stands out! Their service personnel were knowledgeable and friendly.

21 June 2025

H

Hannah Nguyen

Superb quality! Their customer service representatives were friendly and very knowledgeable.

10 May 2025

C

Caleb Carter

Great product! The support staff provided clear and professional guidance.

30 June 2025