Plastic Manufacturing: Top Factories and Reliable Suppliers You Can Trust

Are you in need of a dependable supplier for your plastic material manufacturing? At Jiangsu Dahai Plastics Co., Ltd., we bring extensive industry experience, specializing in the production of high-quality plastic materials tailored to your requirements. Our factory in China is equipped with advanced machinery and a skilled workforce committed to excellence. We prioritize timely delivery and competitive pricing, making us a trusted partner for businesses globally. Our focus on sustainability and innovative methods allows us to offer a diverse range of plastic materials suited for various applications. Whether you need custom designs or bulk quantities, we are ready to support you at every stage. Collaborate with us to enhance your production capabilities and achieve your market goals efficiently.In-Depth Analysis of Methods Plastic Material Manufacturing Process Guarantees Peak Performance Leads the Global Market

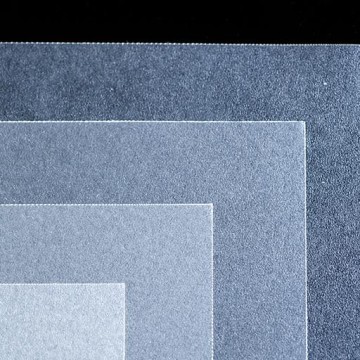

In today's competitive landscape, the manufacturing process of plastic materials plays a pivotal role in determining a company's ability to deliver high-quality products that meet global market demands. An in-depth analysis of various production methods reveals that a focus on innovative technologies and superior material selection not only guarantees peak performance but also positions manufacturers as leaders in the global market. For instance, advanced manufacturing techniques for PVC Films involve precision control over temperature and pressure, ensuring optimal clarity and strength in the final product. By employing cutting-edge production equipment and stringent quality control measures, companies can produce a range of films—including super transparent, ordinary transparent, and specialized types like toy and bath films—tailored to meet diverse consumer needs. This adaptability is crucial in a market where specifications can vary significantly by region and application. Moreover, sustainable practices in plastic production are becoming increasingly important to global buyers who prioritize environmentally conscious sourcing. Companies that invest in high-quality raw materials and eco-friendly processes are not only enhancing performance but also contributing to the industry's shift towards sustainability, ultimately fostering stronger partnerships with international clients seeking responsible suppliers. As the plastic material sector continues to evolve, those who leverage advanced manufacturing techniques and sustainable practices will undoubtedly maintain a competitive edge on the global stage.

In-Depth Analysis of Methods Plastic Material Manufacturing Process Guarantees Peak Performance Leads the Global Market

| Method | Description | Typical Applications | Advantages | Challenges |

|---|---|---|---|---|

| Injection Molding | A manufacturing process for producing parts by injecting molten material into a mold. | Automotive, consumer goods, medical devices | High production efficiency, good surface finish | High initial cost, design limitations |

| Blow Molding | A method for producing hollow plastic parts by inflating hot plastic inside a mold. | Bottles, containers, tanks | Low material waste, quick production | Limited to hollow products, lower strength |

| Thermoforming | A process where a plastic sheet is heated and formed over a mold. | Packaging, automotive parts, trays | Cost-effective for short runs, versatile | Lower strength, limited design complexity |

| 3D Printing | An additive manufacturing process that creates objects by layering materials. | Prototyping, complex geometries | Flexibility in design, rapid prototyping | Slower production speeds, potential material limitations |

Decoding Plastic Material Manufacturing Process Application Outperforms the Competition

S

Sophia Turner

Exceptional quality and durability. Their customer service representatives are true professionals.

23 May 2025

R

Riley Parker

Exceptional quality! The professionalism in post-purchase support was greatly appreciated.

08 June 2025

J

Joseph Martinez

Fantastic quality! Their customer care team is truly dedicated and professional.

23 June 2025

L

Logan Wilson

I absolutely love the quality! The professionalism of the service team was exemplary.

22 June 2025

I

Isabella Scott

Super quality! The service personnel demonstrated a high level of professionalism and care.

05 June 2025

T

Thomas Martin

Fantastic product quality! The professionalism of the support staff was commendable.

12 May 2025