Top Suppliers for PVC Compound Manufacturing in Leading Factories

Are you seeking premium PVC compound manufacturing? Jiangsu Dahai Plastics Co., Ltd. specializes in high-quality PVC compounds tailored to diverse industrial applications. Our rigorous manufacturing process guarantees consistency, strength, and durability, ensuring top-notch materials for our clients. As a reliable wholesale supplier, we prioritize excellence in production, enabling you to access the best products on the market. With years of expertise in supply chains, we provide dependable solutions to meet your unique demands. Partnering with seasoned manufacturers like us ensures innovative materials that enhance your offerings. Our dedication to quality and customer satisfaction sets us apart in the industry. Contact us to discuss how our exceptional PVC compounds can meet your business needs.Popular Pvc Compound Manufacturing Process From Concept to Delivery Factory-Direct Excellence

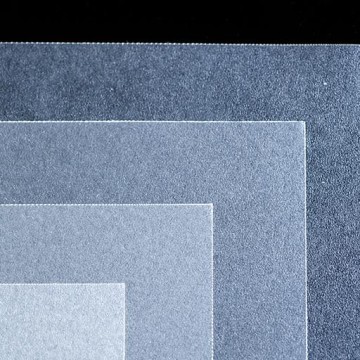

In today’s competitive manufacturing landscape, understanding thE Pvc compound production process is essential for global buyers seeking reliable suppliers. The journey from concept to delivery involves several key steps that ensure quality and efficiency. Initially, it begins with the selection of high-quality raw materials, where the characteristics of the PVC compounds are defined based on the specific requirements of the end products. The formulation phase includes meticulous planning for various applications—be it super transparent film or specialized toy and bath films. The mixing and processing stages are critical, employing advanced technology to guarantee homogeneity and performance. After thorough quality checks, the processed PVC is transformed into films through various techniques, ensuring that each finish meets global standards for transparency, durability, and application-specific properties. The final phase involves comprehensive testing before the products are packaged and shipped directly to clients. By adhering to rigorous standards and continuous innovation, manufacturers can deliver exceptional quality PVC films, making them a preferred choice for international buyers seeking reliability and excellence in their products.

Popular PVC Compound Manufacturing Process From Concept to Delivery Factory-Direct Excellence

| Process Step | Description | Timeframe | Key Equipment | Quality Control Measures |

|---|---|---|---|---|

| Material Sourcing | Select high-quality PVC resin and additives from reliable suppliers. | 1 week | Supplier Database | Supplier Audits |

| Blending | Mix PVC resin with additives to achieve desired properties. | 2 days | High-Intensity Mixer | Batch Testing |

| Compounding | Process blended material through a extruder to create compound pellets. | 3 days | Single-Screw Extruder | In-line Quality Checks |

| Cooling | Cool extruded compounds to stabilize material properties. | 1 day | Cooling System | Temperature Monitoring |

| Packaging | Package finished pellets for storage and shipment. | 1 day | Packing Machine | Final Inspection |

Not to Be Missed Pvc Compound Manufacturing Process Winning in 2025 Custom Solutions,

O

Olivia Davis

Superb product quality! The after-sales team was attentive and well-informed about the product.

28 June 2025

A

Avery Allen

I loved the product! Their customer service team is clearly well-trained and dedicated.

27 June 2025

M

Mason Perez

Quality item! The staff provided excellent support and answered all my questions promptly.

15 May 2025

A

Asher Nguyen

Quality is superb! Their service staff ensured everything was handled with care.

26 June 2025

H

Hailey Walker

I truly appreciate the high quality! The service team is skilled and attentive.

08 June 2025

S

Sarah Wilson

Impressive quality! Their professional after-sale service team made all the difference.

15 June 2025