Top PVC Manufacturing Processes: Leading Factories and Trusted Manufacturers

As an industry leader, we pride ourselves on our expertise in PVC manufacturing. Our state-of-the-art facilities ensure the highest quality products tailored to your needs. Each step of our manufacturing process emphasizes quality and efficiency, positioning us as a reliable partner for businesses. At Jiangsu Dahai Plastics Co., Ltd., we value performance and reliability, applying rigorous standards in our production. We offer both custom solutions and standard Pvc Products, guaranteeing outstanding value without compromising on quality. Partner with us to elevate your product offerings and optimize your supply chain with our superior PVC solutions. Together, we can enhance your business.Curated Selection of Pvc Manufacturing Process Where Service Meets Innovation From Concept to Delivery

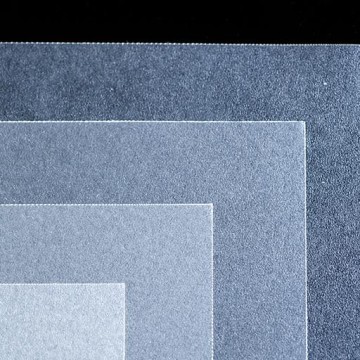

At Jiangsu Dahai Plastics Co., Ltd., we pride ourselves on being at the forefront of PVC manufacturing since our establishment in 1996. Our curated selection of PVC films includes super transparent, ordinary transparent, toy, bath, raincoat, and electrical taPe Films, showcasing our commitment to quality and innovation. As a private enterprise dedicated to technological advancement, we seamlessly blend service and manufacturing excellence, ensuring our clients receive products that meet their specific needs, from concept to delivery. Our state-of-the-art production processes leverage cutting-edge technology, which allows us to create films that not only comply with global standards but also cater to diverse applications across various industries. By focusing on innovation, we continuously optimize our production capabilities, enabling us to respond swiftly to market demands while maintaining competitive pricing and superior service. This commitment to customer satisfaction positions us as a reliable partner for global buyers seeking quality PVC solutions. By choosing Jiangsu Dahai Plastics, you are not just opting for a product; you are entering a partnership that prioritizes your unique requirements and delivers tailored solutions. Our experienced team is dedicated to ensuring a smooth procurement process, guiding you through every step, and providing support even after delivery. Join us in shaping the future of PVC manufacturing, where quality, service, and innovation converge to meet your business needs.

Curated Selection of Pvc Manufacturing Process Where Service Meets Innovation From Concept to Delivery

| Process Stage | Description | Duration (Days) | Innovation Aspect |

|---|---|---|---|

| Concept Development | Initial design and formulation of PVC product | 5 | Use of CAD software for design accuracy |

| Material Selection | Choosing the right type of PVC resin and additives | 3 | Incorporating sustainable materials |

| Manufacturing | Melting and shaping the PVC material | 10 | Automation in extrusion processes |

| Quality Control | Testing the PVC products for standards compliance | 7 | Utilizing smart sensors for real-time monitoring |

| Packaging | Preparing products for shipment and storage | 2 | Innovative eco-friendly packaging materials |

| Delivery | Shipping products to customers | 4 | Tracking systems for efficient logistics |

Step-by-Step Guide To Pvc Manufacturing Process Where Service Meets Innovation Service

J

James Wilson

Consistently high quality! Their support team is prompt and informative.

23 May 2025

J

Jackson Hall

Great quality! The customer service team was responsive and knowledgeable.

11 June 2025

L

Lily Scott

Excellent quality! The customer service representatives were helpful and knowledgeable.

23 May 2025

M

Maya Davis

I am incredibly impressed with the quality! The service staff was eager to assist.

15 June 2025

C

Chloe Turner

The quality is top-notch! The after-sale service proved to be incredibly reliable and professional.

27 May 2025

D

Daniel Patel

Impressive quality! The support team’s expertise made my experience much easier.

21 June 2025