Maximize Quality with Top PVC Polymerization Suppliers and Manufacturers

As a premier manufacturer based in China, we specialize in high-quality PVC polymerization products. Our state-of-the-art facility is equipped with advanced technology, ensuring that every batch adheres to stringent industry standards. With extensive experience in the B2B sector, we focus on understanding client needs and providing exceptional customer service alongside our top-tier products. Our efficient and reliable PVC polymerization process enables confident sourcing of materials tailored to your specifications. Choosing us means entering a partnership rooted in trust and quality, capable of handling bulk orders or specialized requests. Let us enhance your supply chain and support your production objectives with competitive pricing and customized solutions. Contact us today to start building a successful collaboration.Methods To choosE Pvc Polymerization Ahead of the Curve Factory

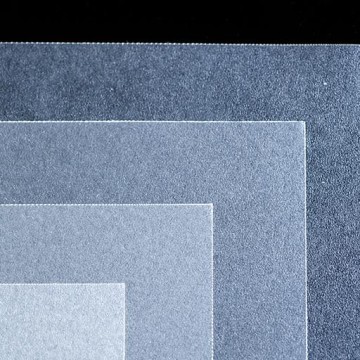

When it comes to selecting the right PVC polymerization methods for your manufacturing needs, staying ahead of the curve can significantly enhance your product quality and operational efficiency. PVC, or polyvinyl chloride, is a versatile thermoplastic widely used in various applications, from packaging to construction. The methods of polymerization can greatly influence the properties of the final product, including clarity, strength, and flexibility. Therefore, it is crucial for global buyers to understand the different methods available and their implications on production. One effective approach is suspension polymerization, which offers excellent control over particle size and leads to high purity polymers, making it ideal for applications such as super transparent films. Emulsion polymerization, on the other hand, enables the production of fine, stable emulsions, contributing to the creation of films that are not only durable but also lightweight. Buyers should also consider bulk polymerization, which often results in high molecular weight PVC, suitable for demanding applications like electrical insulation films. Each method has its advantages, and choosing the right one will depend on the specific requirements of your end products. Furthermore, continuously monitoring industry trends and technological advancements in PVC production will help buyers make informed decisions. Collaborating with manufacturers who prioritize innovation and quality can lead to significant competitive advantages. By leveraging new polymerization techniques and materials, companies can enhance the performance characteristics of their PVC products while reducing environmental impact, thus meeting the growing market demand for sustainable solutions. Ultimately, understanding the nuances of PVC polymerization will empower buyers to make strategic choices that align with their business objectives.

Methods To Choose PVC Polymerization Ahead of the Curve Factory

| Method | Description | Advantages | Limitations |

|---|---|---|---|

| Suspension Polymerization | A technique where PVC particles are suspended in a liquid medium to polymerize. | High molecular weight, easy processing. | Requires careful control of temperature and stirring. |

| Emulsion Polymerization | Involves the polymerization of PVC in an emulsion system. | Produces fine particles, energy efficient process. | Stability of emulsion can be an issue. |

| Bulk Polymerization | Direct polymerization of monomers in bulk with no solvent. | High purity and low cost. | Difficult heat removal and potential for thermal degradation. |

| Solution Polymerization | Polymerization carried out in a solvent solution. | Easy control of viscosity, good for processing. | Solvent recovery can be complex. |

Best Brands For Pvc Polymerization Outperforms the Competition Where Service Meets Innovation

E

Ethan Brown

Great quality overall! Their customer support team went above and beyond to assist me.

01 July 2025

S

Sarah Wilson

Impressive quality! Their professional after-sale service team made all the difference.

15 June 2025

A

Anna Thompson

Outstanding quality! The after-sales service ensured my satisfaction.

03 July 2025

T

Thomas Martin

Fantastic product quality! The professionalism of the support staff was commendable.

12 May 2025

O

Oliver Brown

Great quality! The service staff were well-informed and handled my request expertly.

08 May 2025

A

Aurora Davis

Exceptional quality! I was very impressed with the knowledge and professionalism of the service team.

01 June 2025