Top Manufacturers of Thin Flexible Plastic from China - Quality & Suppliers

When sourcing thin Flexible Plastic, quality and reliability are paramount. Renowned manufacturers, like Jiangsu Dahai Plastics Co., Ltd., specialize in delivering innovative plastic solutions suited for a variety of industries, including packaging and automotive applications. They offer a wide selection of customizable options tailored to meet specific project needs. Each product is meticulously crafted to ensure durability and flexibility while maintaining the highest standards of quality. Partnering with us means engaging with a company that prioritizes strong relationships and exceptional service alongside top-tier products. Enhance your projects with our superior thin flexible plastic solutions!

Key Methods For Thin Flexible Plastic Service Backed by Expertise Outperforms the Competition

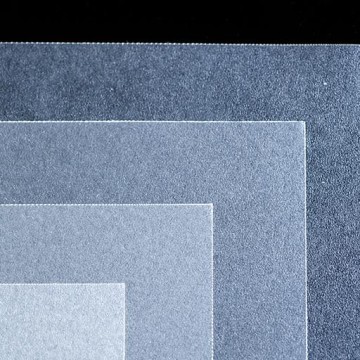

At Jiangsu Dahai Plastics Co., Ltd., we take pride in our commitment to quality and innovation in the realm of thin flexible plastic products. Established in 1996, our expertise spans over two decades, making us a trusted partner for global buyers seeking reliable PVC films. Our state-of-the-art technology allows us to produce a wide range of products, including ultra-clear film, standard transparent film, toy film, bath film, raincoat film, and electrical taPe Film, each tailored to meet the diverse needs of various industries. What sets us apart from the competition is our dedication to excellence backed by our extensive experience in plastic production. We understand the nuances of PVC film applications, ensuring that our products not only meet but exceed industry standards. Our super transparent films are renowned for their clarity and durability, making them ideal for packaging, displays, and numerous other applications where visibility and protection are paramount. By leveraging our technical know-how and a customer-centric approach, we consistently deliver solutions that enhance operational efficiency and product performance. Partnering with Jiangsu Dahai Plastics means choosing a supplier that prioritizes quality, innovation, and customer satisfaction. We work closely with our clients to understand their specific requirements and provide tailored solutions that stand out in the marketplace. As global procurement becomes increasingly competitive, aligning with a company that combines expertise with a broad product range allows buyers to stay ahead of the curve, ensuring they receive the best value and quality in thin flexible plastic solutions.

Key Methods For Thin Flexible Plastic Service Backed by Expertise Outperforms the Competition

| Method | Description | Advantages | Applications |

|---|---|---|---|

| Injection Molding | A manufacturing process for producing parts by injecting material into a mold. | High precision, efficient for mass production. | Packaging, automotive parts, consumer goods. |

| Blow Molding | A process used to create hollow plastic parts by inflating a heated plastic tube. | Ideal for large volume production, lightweight products. | Bottles, containers, large plastic tanks. |

| Vacuum Forming | A thermoforming process where a plastic sheet is heated and molded over a shape. | Cost-effective for low-volume production and rapid prototyping. | Trays, packaging, industrial covers. |

| 3D Printing | Additive manufacturing technique that creates objects layer by layer. | Highly customizable, suitable for complex designs. | Prototypes, customized parts, art pieces. |

Ultimate Guide To Thin Flexible Plastic Service Backed by Expertise Pioneers in the Field

E

Emily Carter

The product exceeded my expectations in terms of quality. Moreover, the after-sale service was top-notch and very supportive.

26 June 2025

W

William Scott

The quality speaks for itself. Their service staff was attentive and provided great insights.

07 June 2025

E

Ella Johnson

Wow! The product quality is excellent, and the dedication of the support team is clear.

11 May 2025

Z

Zoe Clark

Product quality is outstanding! The service representatives were very skilled and supportive.

10 June 2025

C

Chloe Harris

Outstanding quality! Their support staff were professional and very quick to help.

10 May 2025

J

James Kim

Fantastic quality! The after-sale service really impressed me with their care and knowledge.

26 May 2025